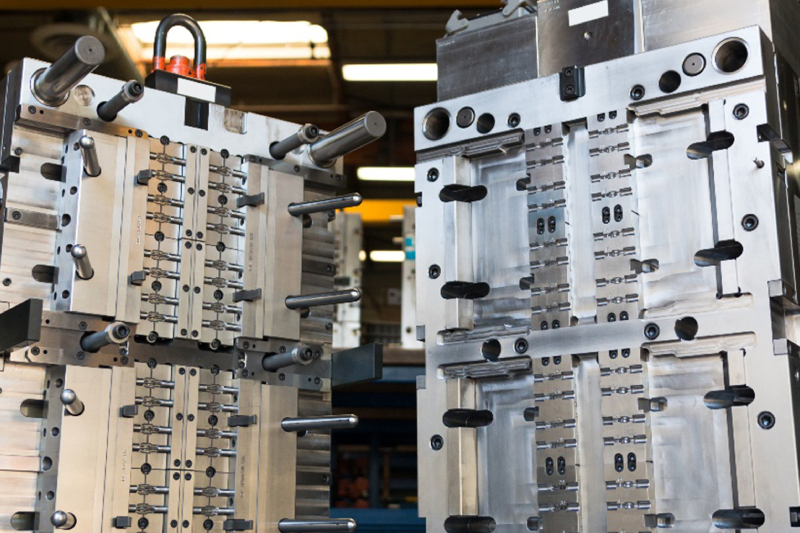

What Is the Plastic Injection Molding Process?

Plastic injection molding is the manufacturing process of making mechanical components or any of its parts by the injection of molten plastic material into a mould and solidifying them. The injection mold manufacturer prefers this as it is a versatile one, and also it helps to reduce the production cost and produces high-quality plastic parts. The injection molding company uses this process for the production of plastic parts in huge volumes. The below article will see the latest trends and innovations happening in the plastic injection molding industry.

Latest Trends In Injection Molding

Here are some latest trends and innovations that are happening in the plastic injection molding industry.

- Micro Injection Molding

Micro Injection Molding is the manufacturing process of making molding parts at a micro-level. Sometimes, it is quite surprising to know that huge machines can produce small items such as tv remote, key chain, all the items inside a mobile phone, etc. These days, the newest trend is to produce much smaller things than the items mentioned above. In micro injection molding, there are very few to no chances of errors. However, it is quite easy to find out if something goes wrong and much easier to fix it. We can see many examples of micro injection molding around us daily such as watches, bracelets, hair combs, etc.

- High-Performance Materials

The latest trend with the plastic injection molding industry is the use of temperature and corrosion-resistant materials. For example, automotive industry injection molding manufacturers often prefer lasting, corrosion-resistant materials as they have proven to improve the longevity of the components. Because of these high-performance materials, the manufacturers could reduce the weight of various other parts of the final product to enhance the automobile’s fuel efficiency. If the latest studies are to be believed, then every 10% of weight reduction in the vehicle has resulted in a 4-7% reduction in fuel consumption.

- Eco-Friendly Materials

Eco-friendly materials are quite important for some manufacturing contracts. It is actually of social and general concern to many manufacturers and entrepreneurs. Thermoplastic materials can be reclaimed easily through melting. Manufacturers often prefer less plastic, non-plastic, etc., so that it can reduce environmental pollution. Most such materials are mostly plant-generated, and they can be made from reproducible bases like flax, corn, etc.

- Automation

The recent trends show that plastic molding manufacturers often prefer automation. However, you cannot say that automation is an innovation because innovations happen in the automation industry every other day. One such automation is the usage of robotics technology to advance the manufacture of plastic injection molds. When one says putting robots in the manufacturing factories, people can get confused about how a robot can replicate human works. Sometimes they even wonder about the errors that can happen because of robotic intervention. However, if a manufacturer opts for robotic-quality inspection, they can enjoy many benefits. For example, after the production of the plastic parts, there is a process of reviewing the process to check for any errors. If humans do this process, there is a chance that they might miss the error, and eventually, the plastic part will be sent for shipping with damages. However, if robots are in charge of the reviewing process, they can scrutinize the process and find any errors before the product is sent to shipment.

- Software Enhancement

There are multiple software these days that can improve the plastic parts and the mold designs. They can also enhance the whole injection molding manufacturing process. With the new software, manufacturers can easily improve the quality of the designs and ensure that they get more production with less cost. Numerous new software can enhance the ability to control the way melted plastics flow in the injection molding process. This helps the manufacturers to predict any defects in the manufacturing process. In addition, the software can help the designers to evaluate any errors and make necessary changes in the parts early in the designing process.

Even though the above are the recent trends in the plastic injection molding industry, there will be more innovation in technology in the future, especially in the plastic injection molding industry. Know More